Page 878 - Demo

P. 878

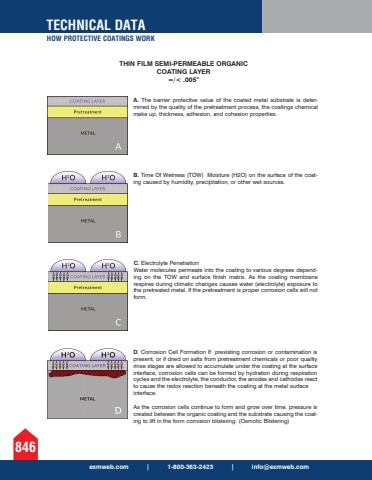

TECHNICAL DATAHOW PROTECTIVE COATINGS WORK846exmweb.com | 1-800-363-2423 | [email protected]. The barrier protective value of the coated metal substrate is determined by the quality of the pretreatment process, the coatings chemical make up, thickness, adhesion, and cohesion properties.B. Time Of Wetness (TOW) Moisture (H2O) on the surface of the coating caused by humidity, precipitation, or other wet sources.C. Electrolyte Penetration Water molecules permeate into the coating to various degrees depending on the TOW and surface finish matrix. As the coating membrane respires during climatic changes causes water (electrolyte) exposure to the pretreated metal. If the pretreatment is proper corrosion cells will not form. D. Corrosion Cell Formation If prexisting corrosion or contamination is present, or if dried on salts from pretreatment chemicals or poor quality rinse stages are allowed to accumulate under the coating at the surface interface, corrosion cells can be formed by hydration during respiration cycles and the electrolyte, the conductor, the anodes and cathodes react to cause the redox reaction beneath the coating at the metal surface interface. As the corrosion cells continue to form and grow over time, pressure is created between the organic coating and the substrate causing the coating to lift in the form corrosion blistering. (Osmotic Blistering) THIN FILM SEMI-PERMEABLE ORGANIC COATING LAYER =/< .005%u201d